Wrapping Up the Pattern: Lasercut

As pleasant as this pattern was visually, there was just NO WAY it was going to be replicable within 4x4" - it was just too detailed with some really minuscule elements that didn't carry across rescaling.

Once that was clear, I spent a class redesigning the pattern, from its original inspiration sources, into something familiar to the above concept but lasercut-able.

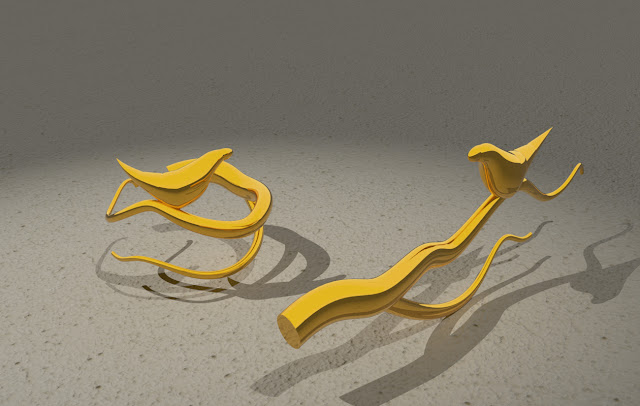

Knowing it was going to be cut from its background, but also that it could only be coloured through burning, I worked to those limitations/ possibilities. I reworked the pattern so that it would also work in greyscale, and then set up a series of small delicate lines and rings that would be hard to fashion without the precision of a laser. Paper or softer plastics would be floppy, so it was important to me that the wood's faktura would be appreciated instead of overlooked.

Comments

Post a Comment